Innovation is essential to success in the field of electronics. As the need for smaller and more flexible performance electronic devices continues to increase, companies are seeking new ways of revolutionizing product assembly. Flex circuit manufacturing is one new technology that has been the subject of a lot of attention.

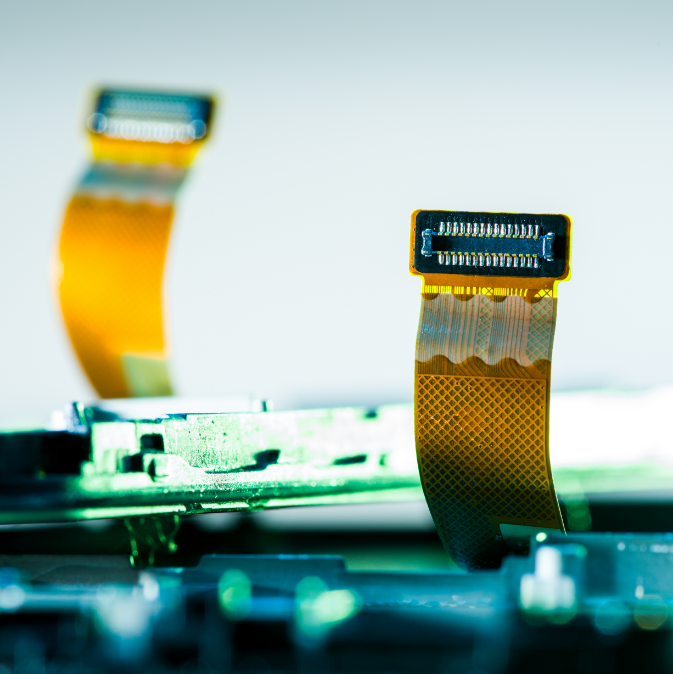

Flex circuits are also referred to as flexible printed circuit board (PCBs) and have many advantages over rigid PCBs. These remarkably versatile circuits are made to bend in a variety of ways, twist, and adapt to different shapes, making them ideal for applications that require intricate designs, limitations on space, or increased durability.

Flex circuits enable manufacturers to extend the boundaries of design by providing a flexible foundation that adapts to the form of the device. This flexibility allows for the creation of more compact and imaginative designs that ultimately result in smaller and lighter products. Imagine a smartphone that curves effortlessly around your hand. A health tracker discreetly fitted around your wrist. Or even a smart device with an ergonomic, smooth design. Flex circuits empower designers and engineers to turn these concepts into reality, unlocking an entirely new realm of possibilities for product development.

The endurance of circuits that are flexible is what separates them from rigid counterparts. Traditional PCBs can suffer damages from shock, vibration and continual bending. Flex circuits are constructed from materials that are resistant to these elements, making them extremely reliable. This particular durability is crucial in industries such as automotive, aerospace and medical, in which electronic components have to withstand extreme environments without compromising their performance.

The manufacturing techniques employed in flex circuit production contribute significantly to their impressive capabilities. Flexible circuits, in contrast to rigid PCBs are made from a flexible substrate such as polyester or polyimide. The substrate serves as the core of the circuit, allowing it to bend or turned while retaining electrical connectivity. Through the use of advanced manufacturing processes such as flex circuit manufacturing, manufacturers can precisely cut circuit traces, connect complex interconnects and connect components directly to the flexible substrate.

Surface mount technology, also known as SMT, permits the integration of components onto flexible circuits. This allows for greater functionality and flexibility of these circuits. With SMT, manufacturers can mount electronic components directly on the surface of the circuit, removing the need for large connectors and minimizing the overall size of the device. This method of streamlined design not only helps save space, but also increases signal integrity, reduces the weight and boosts thermal management.

The flex circuit manufacturing techniques also permit rapid prototyping, and can be scaled up to meet the needs of larger numbers. Flexible circuit designs permit rapid iterations in the prototyping phase, which speeds up the process of developing a product. Because of their capability to be manufactured in high quantities by using automated manufacturing processes, flex circuits provide cost-effective solutions for high volume production. Flexible circuits are an excellent option for businesses looking to bring their innovative ideas quickly into the marketplace.

The availability of dependable flex-circuit manufacturers is increasingly crucial as the demand for electronic devices that can be flexed to increase. It is vital to partner with reliable, experienced manufacturers to ensure the accuracy and reliability in the manufacturing of flex circuits. They possess the expertise and experience to guide you through the design process, provide valuable insight into material selection and ensure compliance with industry standard.

In the end, flex-circuits are essential components that enable modern electronic assemblies to reach the highest possible level of complexity. From displays used in consumer goods to military applications, flex circuits are at the center of these complex systems. They are able to move effortlessly across small areas, flexible substrates offer engineers the ability to create designs that are feature-rich and still fit into the tight dimensions of assembly footprints. While it’s true that a number of other types of circuit routing exist but their electrical and mechanical characteristics aren’t as impressive as those provided by flexible assemblies when it comes to meeting tough size restrictions. Flex circuits are the most suitable option for projects that require complex interconnections, combining several technologies into an expertly designed package.